재생 에너지

EMPOWERING SOLAR CELL MANUFACTURING WITH SUSTAINABLE WATER SOLUTIONS

Solar photovoltaic cells are rapidly becoming a more prominent and critical part of our renewable energy future. Gradiant works closely with industry-leading manufacturers to solve their water and wastewater challenges, innovating novel solutions, optimizing capital scope, and minimizing operational costs.

요약 정보

위치: Tamil Nadu, India

최종 사용자: One of India’s largest companies’ Solar PV

Manufacturing business

솔루션: 산업 폐수 및 재활용

산업: 재생 에너지

급수 공급원: Process Wastewater

기술: ROI, Selective Contaminant Extraction (SCE), CURE Chemicals

시스템 용량: 8,100 m3 /day

커미셔닝: 2024

배달 모델: Design-Build, Commissioning, Operate & Maintain (O&M)

도전 과제

솔루션

Gradiant is delivering a high recovery RO Infinity (ROI) system, and pretreatment and ultrafiltration (UF) to the client for an industrial wastewater and recycling solution. The integrated facility will treat the complicated wastewater streams from solar PV manufacturing to allow for recycling and reuse in their upstream processes, helping our client minimize their water footprint and meet sustainability goals.

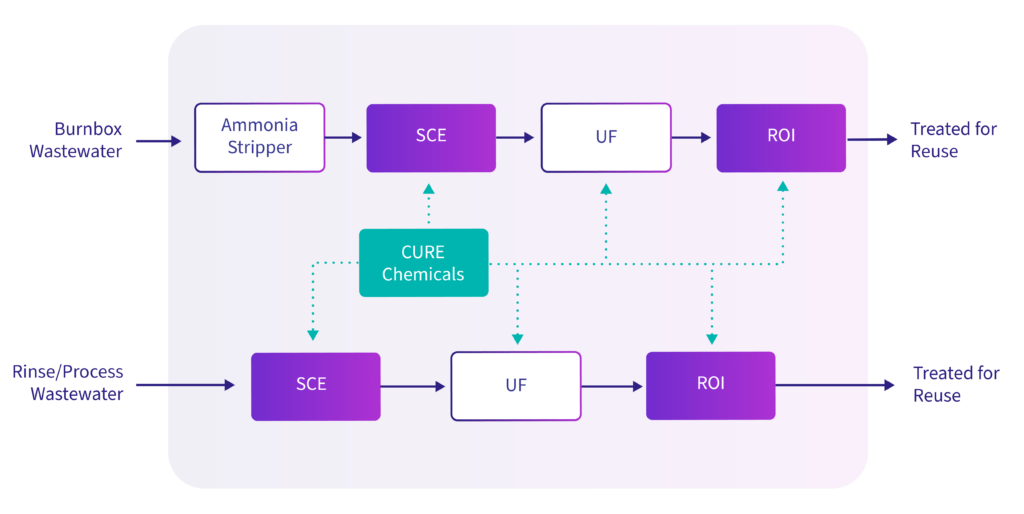

Gradiant created two flowsheets for the process and burnbox effluent streams, combining selective contaminant extraction (SCE) and RO Inifinty (ROI) technologies for both ammonia and fluoride removal, as well as treating water that is reused on-site. Gradiant is also providing chemicals and O&M services to ensure consistent and reliable operations.

혜택

By taking a value engineering approach early in the project, the Gradiant team was able to fast-track a viable solution for the customer. The client recognized this was a significant feat given the complex waste streams and a compressed project timeframe, which could only have been achieved through simplifying startup, commissioning, and ongoing operations for the client as part of an integrated solution.

The ROI system will recover up to 85% of the wastewater for on-site use and achieve ZLD limits. The future-proofed design will also increase plant capacity as the customer innovates new products and creates additional waste streams.

영향력 통계

4GW

PV Cell & Module Manufacturing

Facility

85%

Up to 85% Recovery of wastewater for beneficial reuse on-site

6,885

Up to 6,885 m3/day in freshwater

savings

71,500

Metric tons CO2 offset from PV

cells & modules

그림 및 이미지

Operation and Maintenace Process Flow Diagram

법적 면책 조항

본 문서는 일반적인 정보 제공만을 목적으로 합니다. 어떠한 보증이나 보장도 제공되거나 묵시적으로 제공되지 않으며 Gradiant는 여기에 포함된 정보에 대해 구속되거나 이에 대한 책임을 지지 않습니다. 고객은 실제 현장, 지리적 및 공장 조건, 사양, 요구 사항, 폐기, 관련 법률 및 규정을 포함하여 본 문서의 정보가 고객의 사용에 적합한지 여부를 결정할 전적인 책임이 있습니다. 본 문서는 본 문서에 포함된 모든 특허 또는 상표를 포함하되 이에 국한되지 않는 Gradiant의 지적 재산입니다. 본 문서의 배포는 Gradiant의 지적 재산의 이전을 의미하지 않으며, 이를 의미하지도 않습니다.

Gradiant, Gradiant 로고 및 ™ 또는 ®로 표시된 모든 서비스 마크는 별도의 언급이 없는 한 Gradiant Corporation의 계열사가 소유합니다. © 2024 Gradiant.