Raffinage et produits chimiques

SUSTAINABLE AND COST-EFFECTIVE ZLD SOLUTIONS FOR DYE MANUFACTURING

Archroma, a global diversified provider of specialty chemicals for performance textiles, was in need of a sustainable and cost-effective solution to treat its dye wastewater. Gradiant answered with a Zero Liquid Discharge (ZLD) facility featuring the RO Infinity with CFRO and Free Radical Oxidation (FRO) technologies.

Faits marquants

Localisation: Mahachai, Thaïlande

Utilisateur final: Archroma

Solution: Zéro rejet liquide

L'industrie: Chemicals

Source d'eau d'alimentation: Eaux usées de teinture

Technologie: RO Infinity avec CFRO, oxydation radicale libre

Configuration du système6 étapes de RO Infinity CFRO et 1 train de FRO

Capacité du système: 1 000 m3 /jour

Date en ligne: novembre 2023

Modèle de livraison: Conception-construction (CC)

Le défi

Archroma is a global leader in dye manufacturing for the world’s leading apparel brands. Their manufacturing plant in Thailand produces wastewater with high levels of Total Dissolved Solids (TDS) and Chemical Oxygen Demand (COD). The primary challenge was identifying a solution to create a sustainable dye manufacturing process, maximize water reuse, and achieve ZLD. With limited cost-effective options for brine minimization, the client looked to partner with Gradiant to achieve its sustainability goals.

La solution

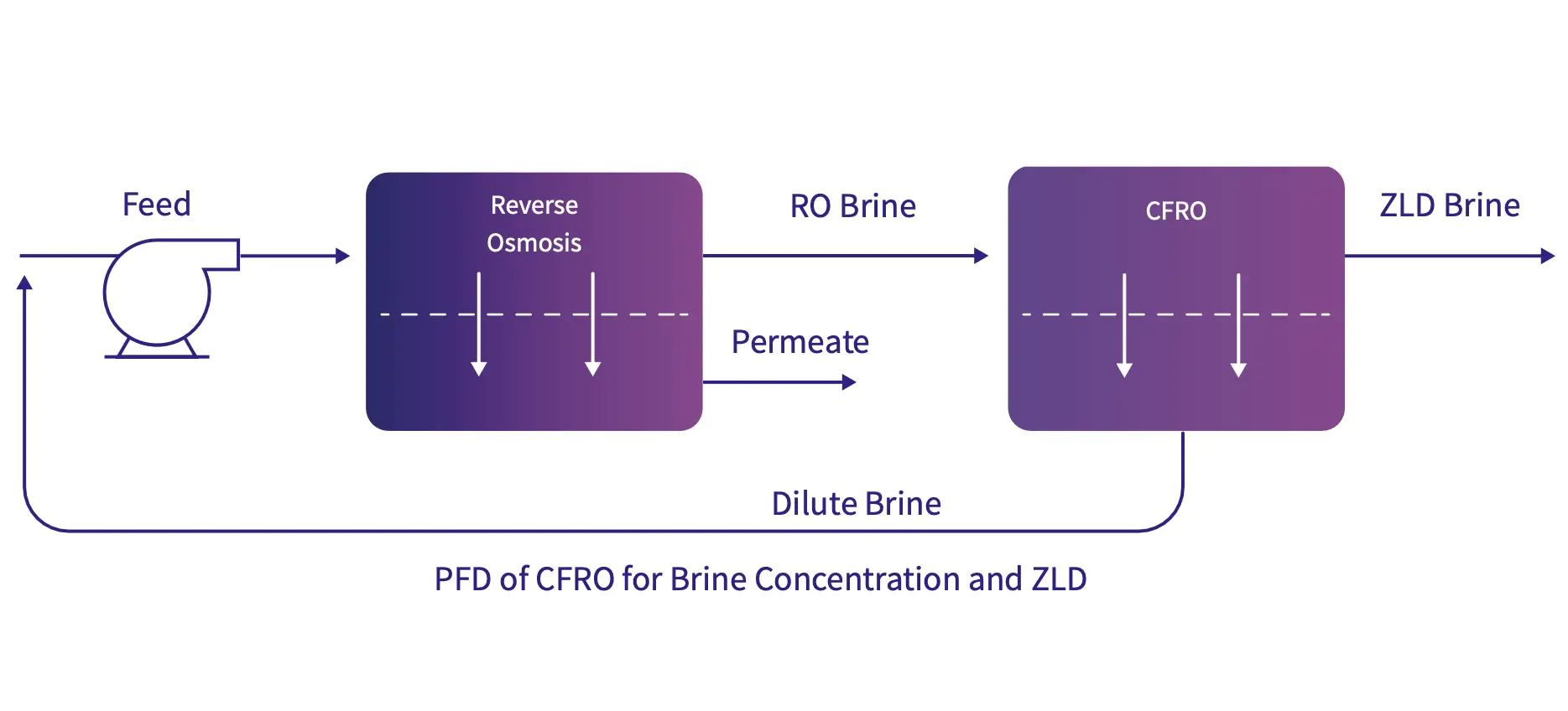

To treat a variety of feedwater quality and to achieve ZLD, Gradiant proposed a robust solution featuring 6 stages of RO Infinity with CFRO and FRO. The CFRO system demonstrated it could concentrate brine recoveries up to 95%. The wastewater was then treated by FRO to remove color by oxidizing the organics. This solution also proved successful to remove high TDS and COD, allowing for the dye wastewater to be reused in the manufacturing process, while saving up to 40% CAPEX compared to Ultra-High Pressure RO (UHPRO).

Les avantages

Gradiant delivered a custom RO Infinity with CFRO system that achieves ZLD, as well as beneficial reuse of the wastewater. The process produces fresh water that contains 24 to 48 times less TDS, and can be reused for dye manufacturing. The FRO technology achieves a colorless brine concentrate stream that can be processed as a by-product for salt preparation and resin regeneration. Gradiant’s RO Infinity is used for the primary solution to reduce fouling and scaling.

Statistiques d'impact

24X-48X

TDS reduction After Treatment

ZERO

Zéro rejet de liquide

40%

Up to 40% CAPEX and OPEX Savings in comparison to UHPRO

50%

More than 50% Energy Savings compared to other Brine Minimization Technologies

Chiffres et images

CFRO Process Flow Diagram

Avis de non-responsabilité

Ce document est destiné à des fins d'information générale uniquement. Aucune garantie n'est donnée ou impliquée et Gradiant n'est pas lié ou responsable des informations contenues dans ce document. Le client a la responsabilité exclusive de déterminer si les informations contenues dans ce document sont appropriées à l'utilisation qu'il en fait, y compris, mais sans s'y limiter, les conditions réelles du site, de la zone géographique et de l'usine, les spécifications, les exigences, l'élimination, les lois et règlements applicables. Ce document est la propriété intellectuelle de Gradiant, y compris, mais sans s'y limiter, tout brevet ou marque commerciale contenu dans ce document. La distribution de ce document n'est pas et n'implique pas le transfert de la propriété intellectuelle de Gradiant.

Gradiant, le logo Gradiant et toutes les marques de service désignées par ™ ou ® sont la propriété de sociétés affiliées à Gradiant Corporation, sauf indication contraire. 2024 Gradiant.