Press Release

May 18, 2022

Gradiant, Technology Leader in Solving Critical Water Problems, Receives Coveted Global Water Awards

Gradiant was honored with “Distinction – Water Technology Company of the Year” at the Global Water Awards 2022 for innovations like CFRO and SmartOps. Synauta, recently acquired by Gradiant, received “Breakthrough Technology Company of the Year” for its AI-driven desalination performance optimization, affirming Gradiant’s leadership in digital and sustainable water solutions.

External Media

December 9, 2021

Planned Fabs Boost Ultrapure Water Demand, a Test for Recycling Tech | Fierce Electronics

Water shortage has been a concern in the Western U.S. and with more proposed chip fabs in those areas, industrial water recycling is critical to avoid scarcity.

Press Release

November 17, 2021

Gradiant Raises over $100 Million in New Funding for Cleantech Water Growth

Gradiant has secured over $100 million in Series C funding, led by Warburg Pincus and Schlumberger New Energy. The investment accelerates Gradiant’s global growth, particularly in Asia Pacific, to deliver cleantech water solutions focused on reuse, recovery, and zero liquid discharge across industries including microelectronics, pharmaceuticals, and food and beverage.

Press Release

September 14, 2021

Gradiant Achieves Strong Growth in Cleantech Water Treatment during the Pandemic

Gradiant secured 26 new water treatment projects in the Asia Pacific region in 2021 YTD, including four long-term DBOOM contracts. The company's cleantech solutions expanded into lithium mining, semiconductors, and industrial reuse, despite COVID-19 disruptions. Gradiant’s team grew by 100 people, highlighting strong regional demand for sustainable water treatment technologies.

External Media

August 20, 2021

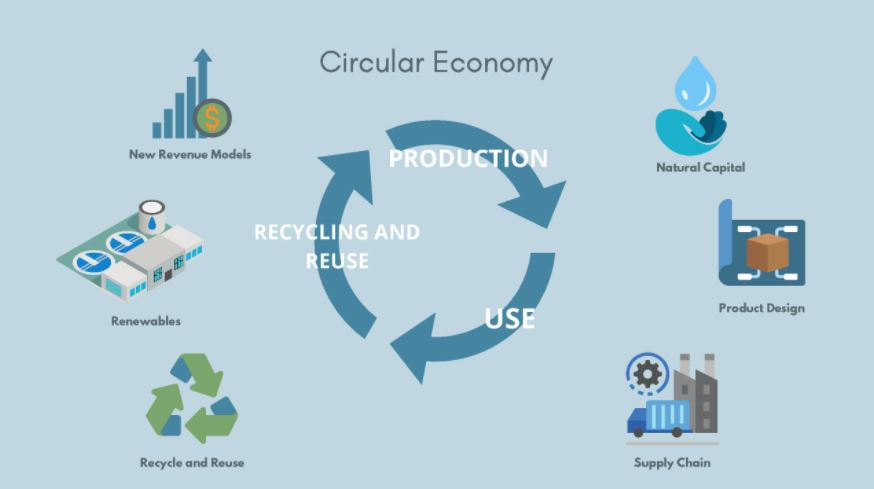

Circular Economy and Clean Technology for a Sustainable Future | The Business Times

In his column in The Business Times, Gradiant Co-Founder Prakash Govindan declares circular economy and clean technology as the keys to a sustainable future.

Press Release

January 26, 2021

Gradiant Posts Robust 2020 Global Performance with 30 Project Wins

Gradiant secured 30 new water and wastewater treatment projects across APAC, the Middle East, and the US in 2020, valued at over USD 400 million. With the launch of SmartOps, its AI-enabled asset management platform, Gradiant continues its momentum in delivering end-to-end solutions for industries including pharmaceuticals, latex, food and beverages, seawater desalination, mining, steel, and chemicals.

Press Release

September 20, 2020

Global Water Treatment Company Gradiant Acquires Sigma Water (Malaysia) as Part of South East Asia Growth Strategy

Gradiant has acquired Malaysia-based Sigma Water Engineering to strengthen its presence across Southeast Asia. The move integrates Sigma’s industrial project delivery strengths with Gradiant’s advanced technologies like CGE and RO Infinity, offering sustainable and cost-effective water solutions. Customers will benefit from enhanced performance and Zero Liquid Discharge capabilities.

Press Release

August 18, 2020

Gradiant Eyes Rapid Growth in Asia Pacific’s US$5B Water Market with 12 Project Wins in H1 2020

Gradiant secures 12 major water and wastewater treatment projects across Asia Pacific, marking multi-fold growth in 2020. These projects span pharmaceuticals, infrastructure, power, textiles, and chemicals, with a value of US$250M. The launch of its RO Infinity (ROI) membrane technology suite strengthens Gradiant’s leadership in solving complex water challenges with innovative desalination and reuse solutions.

Media

For all press inquiries, please contact us here.